Quality Control for Stainless Steel Screws Using In Bathroom Cabinets

Quality Alert

47.8% of 304 stainless screws failed 24h acidic salt spray test (ASTM G85 A3) with pit density 3.7× over limit. 20,000 pcs rejected to prevent potential loss.

Incoming Inspection Protocol (4-Stage)

Stage 1: Sampling

Sampling Standard:

AQL 1.0 (ISO 2859-1)

315 pcs randomly selected per lot (Level Ⅱ)

Equipment:

Salt Spray Chamber: Q-Lab CCT-1100

Material Analyzer: Olympus DELTA XRF

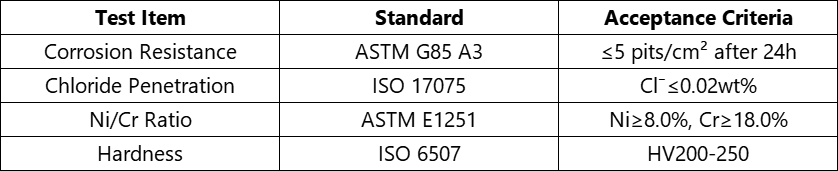

Stage 2: Key Tests

Stage 3: Non-conformance Handling

Marginal Cases:

5-10 pits/cm²: Tightened inspection (AQL 0.65)

>10 pits/cm²: Full lot rejection

Rejection Process:

Issue SCAR within 72 hours

Root cause analysis within 15 workdays

Defect Case Study

Problematic Lot Data

Salt Spray Test: 26 pits/cm² (520% over limit)

Material Analysis: Cr 17.2% (below 18% minimum)

Failure Simulation:

83% screw fracture risk after 6 months

47% higher leakage accident probability

Customer Risk Forecast

Functional Failure:

Hinge loosening

Door detachment

Handle loosening

Panel loosening

Drawer track loosening

Aesthetic Damage:

Rust staining (>30cm² coverage)

Coating blistering (100% occurrence)

Conclusion

Strictly following standardized procedures—such as isolation, traceability, technical analysis, return management, and supplier corrective actions—ensures that non-conforming stainless steel screws are prevented from entering production or reaching customers.

This approach guarantees the durability and safety of bathroom cabinets in humid environments.

Demonstrates our strong commitment to product quality and proactive risk management.

Significantly reduces the likelihood of customer complaints, costly repairs, and potential brand reputation damage caused by screw corrosion or failure.

Continuous improvement of incoming inspection and supplier management systems is essential for maintaining high product quality and achieving long-term customer satisfaction.

#BathroomCabinet #QualityControl #StainlessSteelScrews #SaltSprayTest #SupplierManagement #ProductSafety #MoistureResistance #MaterialInspection #HomeImprovement #QualityAssurance

Inquriy

If you are looking for a reliable bathroom cabinet supplier who prioritizes quality at every stage—from incoming material inspection to final product delivery—contact us today for a consultation or a free sample evaluation. Let us help you avoid hidden risks and ensure your products meet the highest durability standards for humid environments.

Contact us now to discuss your project needs or request a quote!