How Shower Enclosure Packaging Standards Protect Your Product

🛠 Introduction: Packaging Is Not Just a Box

When it comes to shower enclosures, product quality doesn’t end at the factory. One unnoticed scratch, a cracked corner, or a dented profile can ruin months of careful manufacturing—and the biggest culprit? Poor packaging.

In this article, we share real packaging inspection points and practical standards that help ensure your shower doors arrive intact, impress your customer, and protect your brand.

📦 Why Packaging Quality Matters

Packaging serves more than transportation—it’s the final line of defense. Improper protection can result in:

Glass corner chips from under-padded cartons

Deformation of aluminum frames due to internal gaps

Scratched profiles from poorly applied foam

Brand image damage due to torn, wrinkled, or incorrect labels

A good packaging SOP not only avoids claims but builds trust.

✅ 7 Inspection Points from Real SOP

Based on practical shower enclosure quality standards, here are seven must-check items during packaging inspection:

1. Carton Surface Condition

Cartons must be clean, flat, and without damage

No tears, open corners, or dents allowed

Cut edges must be neat

🔍 Visual check under ambient light

2. Foam Protection Fit

All corners and contact points must be protected

Foam must match the carton height and prevent movement

No broken, dirty, or missing foam

📐 Shake test: no sliding inside the box

3. Sealing Tape Application

Tape must run straight across openings

Neatly applied with no folding or misalignment

At corners, tape ends must not exceed 100mm

📏 Standard applies to both export and retail boxes

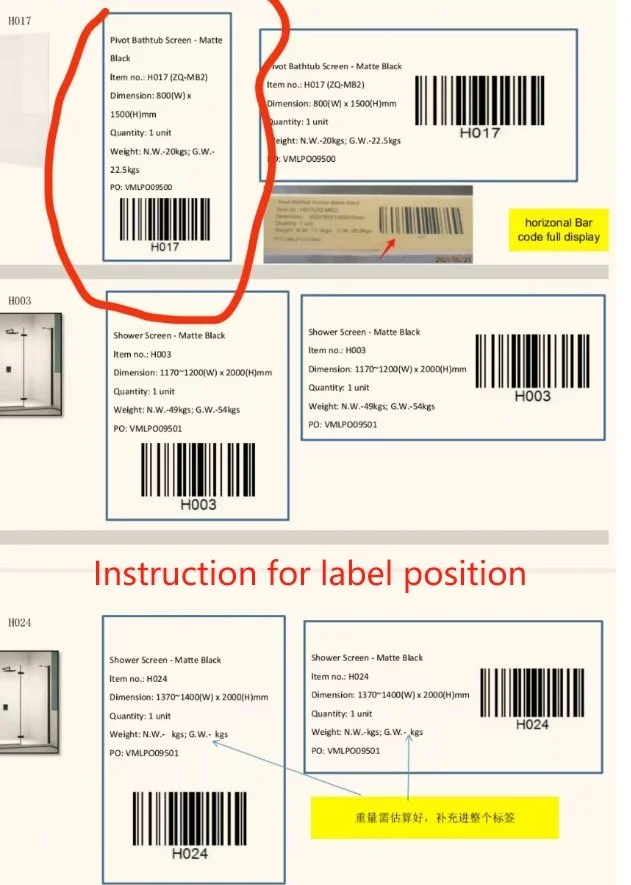

4. Label & Barcode Accuracy

Product labels, images, and barcodes must be correct

Stickers must be flat, aligned, not wrinkled

Barcode must be scannable

📷 Check against order sheet & test scan

5. Shipping Mark Position

Side and front marks must match the product model

No wooden brace should block key labels

Ink must be clear and not smudged

🪵 Check during pallet placement

6. Pallet Structure & Stability

No bark, wet wood, or uneven planks allowed

Pallet must not expose sharp nails

Securely connected to support product during stacking

🧱 Important for container shipping & export

7. Final Placement

Boxes must follow “UP” arrows during stacking

Bottom layer must not be crushed by weight above

No tilting or overhang on pallets

⬆️ Team must follow loading SOP strictly

📸 Visual Example Suggestions

Photo of correctly sealed carton with barcode and labels

Foam inside corner of tempered glass

Clean shipping label + customer branding on box

Wrong vs. right pallet wood slat placement (can be drawn)

#shower-door-packaging

#shower-enclosure-shipping-safety

#foam-protection-for-glass

#carton-sealing-inspection

# export-packaging-SOP

#QualityControl

#SmartMirror

#BathroomProducts

#Wakebath

#SupplierManagement

#ContinuousImprovement

📣Get Packaging That Prevents Returns

Your shower doors deserve more than just bubble wrap.

Contact us to receive more available packing options to reduce potential damage of your shower door during transportation.

🌐: www.wakebath.com

✉️: contact@wakebath.com

Disclaimer

The information is sourced from public channels and is for reference only. If you have any objections, please contact us for deletion.