Why This Matters: Inspect Tempered Glass Quality in Shower Enclosures

Because one bad panel can cost you your margin—and your reputation.

🔥 Why This Matters to You

If you're a distributor, project buyer, or retail category manager, you've felt the pain of damaged or defective glass:

Returns eat up your profit

Customer complaints damage your trust

Installation delays blow project timelines

A single scratch can get your product delisted

And worst of all? You often don’t know there's a problem—until it's too late.

That’s why our inspection process focuses on what matters most to your success: glass that arrives perfect, installs flawlessly, and reflects the quality your brand promises.

✅ 5 Critical Glass Checks That Protect Your Business

1. Edge Chips — The Silent Deal Breaker

Chipped glass edges often go unnoticed during packing—but show up right when your customer opens the box.

Result? Disappointment, refund requests, or worse, liability on-site.

That’s why we strictly control edge smoothness, especially for frameless panels.

🛠 Your benefit: Reduce complaint risk and keep your QC manager off the hotline.

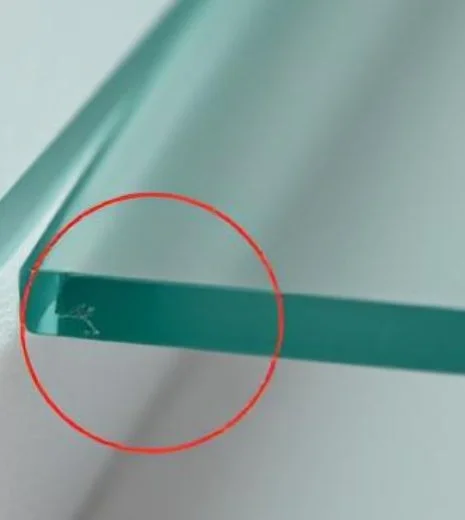

2. Surface Scratches — Small Marks, Big Trouble

A scratch on a high-end shower door doesn’t just look bad—it makes the entire product feel cheap.

We check Class A surfaces under angled light to spot even the finest lines.

✨ Your benefit: No rejected inventory. No unhappy end-users.

3. Bubbles & Inclusions — Hidden Inside, Costly Outside

These internal flaws might seem minor—but they shatter confidence in your QC.

We use light contrast and backlighting to identify even microscopic air pockets or stones.

🔍 Your benefit: Preserve brand credibility with perfect visual clarity.

4. Clamp Marks & Corner Breaks — Installation Nightmares

Installers hate bad corners. So do retailers. Clamp marks and broken edges delay installs, cost labor hours, and risk glass failure.

We check every corner under padding to ensure no hidden cracks slip through.

🧱 Your benefit: Installers trust your product. Fewer job-site issues.

5. Visual Cleanliness — Because First Impressions Matter

Even perfect glass looks bad with smudges or glue residue.

We test-wipe every unit before packing to ensure spotless clarity.

🧼 Your benefit: Impress your clients the moment they unbox it.

📌 Bonus Check: Tempering Mark = Legal Shipment

We ensure every panel is visibly stamped per ANSI Z97.1 or EN12150.

It’s not just compliance—it’s your protection in case of any claim.

🧾 Your benefit: Full traceability, zero liability gaps.

📣 Get Glass That Sells, Not Returns

We understand your real risk: it’s not the cost of the product—it’s the cost of failure.

That’s why we inspect shower enclosure glass the way you would—if you had time to do it yourself.

📩 Get Glass That Sells, Not Returns.

Leave us your concern, we can help you boost more business with less worry.

#TemperedGlassInspection #ShowerDoorQuality #GlassQC #B2BSourcing #ShowerEnclosureStandards #WakeBath #NoReturnsMoreProfit

🔚 DisclaimerThe information is sourced from public channels and is for reference only. If you have any objections, please contact us for deletion.