Understanding Class A/B/C Surfaces in Shower Door Quality Checks

Table of Contents

1.Introduction: The Hidden Language of Quality

2.Why Surface Classification Matters to Your Business

3.Class A Surfaces: The Premium Standard

4.Class B Surfaces: The Functional Middle Ground

5.Class C Surfaces: The Hidden Areas

6.Real-World Application in Shower Door Inspection

7.Common Mistakes That Cost Money

8.Your Quality Classification Action Plan

🎯 Introduction: The Hidden Language of Quality

Ever wonder why some shower doors look flawless while others seem "off" even when they meet basic specifications? The secret lies in understanding surface classification standards—a quality language that separates premium products from mediocre ones.

As someone who's inspected thousands of shower enclosures, I can tell you that Class A, B, and C surface standards aren't just technical jargon. They're your roadmap to consistent quality that customers notice and pay for.

In this article, I'll decode these classifications and show you exactly how to apply them to protect your margins and build customer trust.

💼 Why Surface Classification Matters to Your Business

Here's the reality: Your customers can't articulate surface quality standards, but they absolutely feel the difference.

When you understand Class A/B/C surfaces, you gain:

•Consistent Quality Expectations: No more subjective "good enough" decisions

•Clear Communication: Suppliers know exactly what you expect

•Reduced Returns: Customers receive the quality level they paid for

•Premium Positioning: Justify higher prices with documented standards

The difference between profit and loss often comes down to these surface details that most people overlook.

⭐ Class A Surfaces: The Premium Standard

Class A surfaces are what customers see and touch first—they define your product's perceived value.

What Qualifies as Class A:

•Primary viewing areas: Front-facing glass panels, handles, visible hardware

•Touch points: Door handles, towel bars, any surface customers interact with

•Showroom surfaces: Areas highlighted in marketing photos

Class A Standards:

•Zero visible defects under normal lighting conditions

•Perfect finish consistency across all Class A areas

•No scratches, marks, or blemishes larger than 0.1mm

•Uniform color and texture throughout

Business Impact:

Class A surfaces justify premium pricing and create the "wow factor" that drives word-of-mouth referrals.

🔧 Class B Surfaces: The Functional Middle Ground

Class B surfaces support functionality without demanding perfection—they're the workhorses of your product.

What Qualifies as Class B:

•Secondary viewing areas: Side panels, internal hardware, structural components

•Functional surfaces: Areas that work but aren't primary focal points

•Semi-visible areas: Surfaces seen at angles or in specific lighting

Class B Standards:

•Minor defects acceptable if they don't affect function

•Scratches up to 0.5mm allowed if not in direct sight lines

•Slight color variations permitted within tolerance ranges

•Functional priority over cosmetic perfection

Business Impact:

Class B standards prevent over-engineering while maintaining acceptable quality levels.

🔍 Class C Surfaces: The Hidden Areas

Class C surfaces are rarely seen but still matter for overall product integrity.

What Qualifies as Class C:

•Hidden areas: Behind panels, inside frames, non-visible hardware

•Structural zones: Areas covered by other components

•Service areas: Surfaces only seen during maintenance

Class C Standards:

•Function over form: Must work properly but appearance is secondary

•Larger defects acceptable if they don't compromise performance

•Cost-effective finishes appropriate for hidden areas

•Safety requirements still fully enforced

Business Impact:

Class C standards prevent unnecessary costs while maintaining structural integrity.

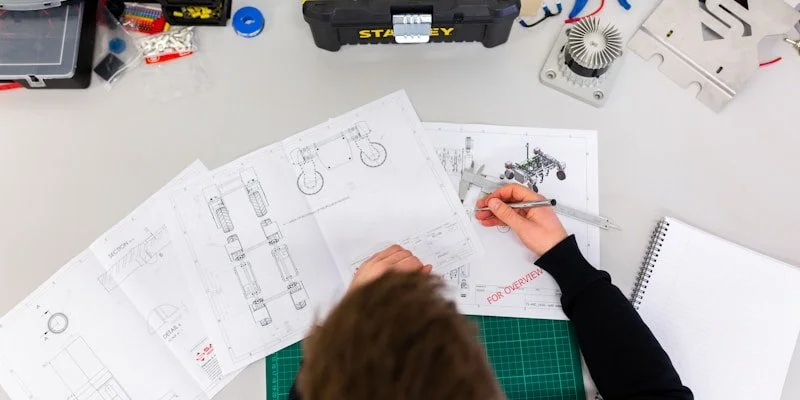

🛠 Real-World Application in Shower Door Inspection

Here's how I apply these standards during actual inspections:

Step 1: Surface Mapping

Before inspection, we map each surface area:

•Front glass panel = Class A

•Door handle = Class A

•Side brackets = Class B

•Internal frame = Class C

Step 2: Lighting Protocol

•Class A: Inspect under showroom lighting (bright, angled)

•Class B: Standard workshop lighting

•Class C: Basic visibility check

Step 3: Documentation

Every defect gets classified and recorded with photos, creating a quality trail that protects both parties.

⚠️ Common Mistakes That Cost Money

Mistake #1: Treating All Surfaces Equally

Cost: 15-25% higher production costs Solution: Apply appropriate standards to each surface class

Mistake #2: Unclear Supplier Communication

Cost: 30% rejection rate on first shipments Solution: Provide surface maps with purchase orders

Mistake #3: Inconsistent Application

Cost: Customer complaints and returns Solution: Train inspection teams on classification standards

📋 Your Quality Classification Action Plan

Week 1: Map Your Products

•Identify Class A, B, and C surfaces on your shower doors

•Create visual guides for your team

•Document current quality issues by surface class

Week 2: Update Supplier Requirements

•Send surface classification maps to suppliers

•Revise quality agreements with specific standards

•Request sample approvals for each surface class

Week 3: Train Your Team

•Educate inspection staff on new standards

•Practice classification on existing inventory

•Create quick reference guides for daily use

Week 4: Implement and Monitor

•Begin full classification inspections

•Track defect rates by surface class

•Adjust standards based on real-world results

🎯 The Bottom Line: Quality That Pays

Remember: Surface classification isn't about being picky—it's about being profitable.

When you apply Class A/B/C standards correctly, you:

•Reduce unnecessary costs on hidden surfaces

•Maximize impact on visible areas

•Create consistent customer experiences

•Build a reputation for reliable quality

📩 Ready to Implement Surface Classification?

Contact us to learn how proper surface standards can optimize your quality costs while improving customer satisfaction.

#SurfaceQualityStandards #ClassABCSurfaces #ShowerDoorQuality #QualityControl #SurfaceInspection #QualityStandards #ShowerEnclosureQuality #BathroomQuality #Wakebath #QualityAssurance #SurfaceClassification #ProductQuality

Disclaimer

The information is sourced from public channels and is for reference only. If you have any objections, please contact us for deletion.