From Data to Durability: How We Ensure Every Shower Door Resists Corrosion

1️⃣ Quality Is Not a Slogan — It’s a Daily Practice

| Test Type | Solution & pH | Corrosivity Level | Common Standard | Typical Purpose |

|---|---|---|---|---|

| Neutral Salt Spray (NSS) | 5% NaCl solution, pH 6.5–7.2 | Moderate | ISO 9227 / ASTM B117 | For coatings like chrome, nickel, zinc |

| Acetic Salt Spray (ASS) | 5% NaCl + Acetic acid, pH 3.1–3.3 | ~3× more corrosive | ISO 9227 / ASTM B287 | For decorative coatings like Ni-Cr |

When we say quality matters, we mean it literally.

Every day, our QC team performs salt spray testing on random samples from production — because beauty in a shower enclosure should last beyond the showroom.

2️⃣ What Is a Salt Spray Test?

Salt spray testing simulates years of exposure to humid, coastal, or high-moisture environments — in just a few days.

We perform three main types:

Neutral Salt Spray (NSS) – simulates normal humidity

Acetic Acid Salt Spray (AASS) – simulates harsher acidic conditions

Copper-Accelerated Acetic Acid Salt Spray (CASS) – the toughest, used for high-end finishes

Each test exposes parts to fine saline mist under controlled temperature and pH. The longer the surface stays free of corrosion, the better its protection.

Common Application

NSS test → used for functional coatings (e.g., zinc, anodizing, powder coatings).

ASS test → used for decorative plating, especially nickel-chrome on brass, ABS, or steel.

For EN 248 (faucet and sanitary fittings), both may appear:

NSS 200 hours → corrosion resistance for metal coatings

ASS 24 hours → decorative surface durability

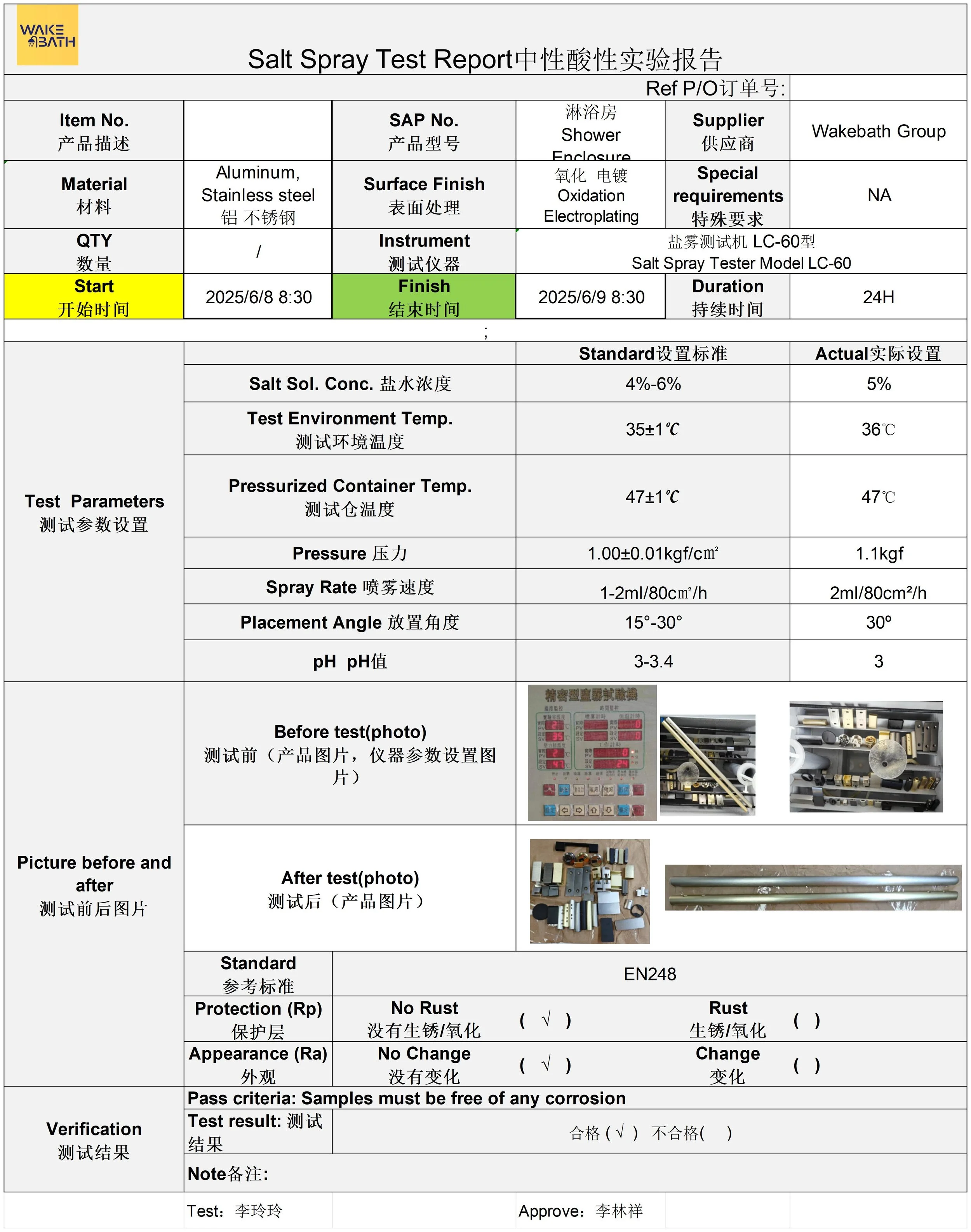

3️⃣ Real Data From Our Daily Testing

Here’s a glimpse from one of our daily QC reports for shower door hardware (June–August cycle):

| Test Item | Type | Duration (Hours) | Result | Remark |

|---|---|---|---|---|

| Roller & Screw | NSS | 200h | ✅ Pass | No corrosion |

| Handle | AASS | 24h | ✅ Pass | No visible damage |

| Aluminum profile | NSS | 240h | ✅ Pass | Excellent finish |

| Chrome hinge | NSS | 200h | ✅ Pass | No pitting or discoloration |

🧠 Note: EN 248 only requires 24h neutral salt spray — our parts exceed that by 8x.

4️⃣ What These Results Mean

Salt spray data isn’t just numbers — it reflects years of coating optimization and process control.

We work closely with plating partners to ensure each nickel-chrome layer meets or exceeds EN 248 and ISO 9227 standards.

Our engineers track:

Coating thickness (Ni ≥ 10 µm, Cr ≥ 0.2 µm)

Surface adhesion and gloss

Post-test corrosion points and visual grading

This consistency helps our clients reduce warranty claims and improve end-user satisfaction.

5️⃣ Our Commitment to Visible Quality

Every test report is a reflection of our promise — not to guess quality, but to measure it.

From material selection to surface finish, our approach is simple:

Test daily. Record accurately. Deliver reliably.

📞 Want to see how we maintain consistency across every batch?

📩 Visit www.wakebath.com to download our product catalog or request sample testing data.

#SaltSprayTest

#CorrosionResistance

#EN248

#QualityControl

#SurfaceFinishing

#BathroomFittings

#PlumbingStandards

#ProductTesting

#MetalCoating

#NickelChrome

#ManufacturingQuality

#SanitaryWare

#LabTesting

#DurabilityMatters

#EngineeringDesign

#Wakebath

6️⃣ Disclaimer

The information is sourced from internal QC records and public standards (EN 248, ISO 9227) for reference only. If you have any objections, please contact us for deletion.