Salt Spray Testing Standard: How Wakebath Ensures Long-Term Corrosion Resistance for Bathroom Hardware

Wakebath performs NSS, AASS, and CASS salt spray testing following GB/T 10125 and EN/ISO standards. Learn how our corrosion-resistance QC process ensures durable bathroom products for global buyers.

⭐ 1. Quality You Can See: Why Salt Spray Testing Matters

Bathroom hardware—such as shower door hinges, rollers, handles, and aluminum profiles—faces constant moisture, temperature changes, and chemical exposure. Corrosion resistance is not optional; it defines product lifetime.

At Wakebath (China), our quality commitment is visible and measurable. Every week, our QC department performs neutral salt spray (NSS), acetic acid salt spray (AASS), and copper-accelerated salt spray (CASS) tests on metal parts, electroplated products, and powder-coated surfaces.

⭐ 2. Standards We Follow

Our Salt Spray Testing Standard (WI-LYF-QC 001) references:

GB/T 10125 — Artificial Atmospheres Corrosion Testing

GB/T 6461 — Rating of Corrosion After Testing

ISO 9227 — NSS / AASS / CASS procedures

EN 248 (applicable to nickel-chrome finishes)

These standards ensure our reports can be recognized by buyers from Europe, North America, the Middle East, and Oceania.

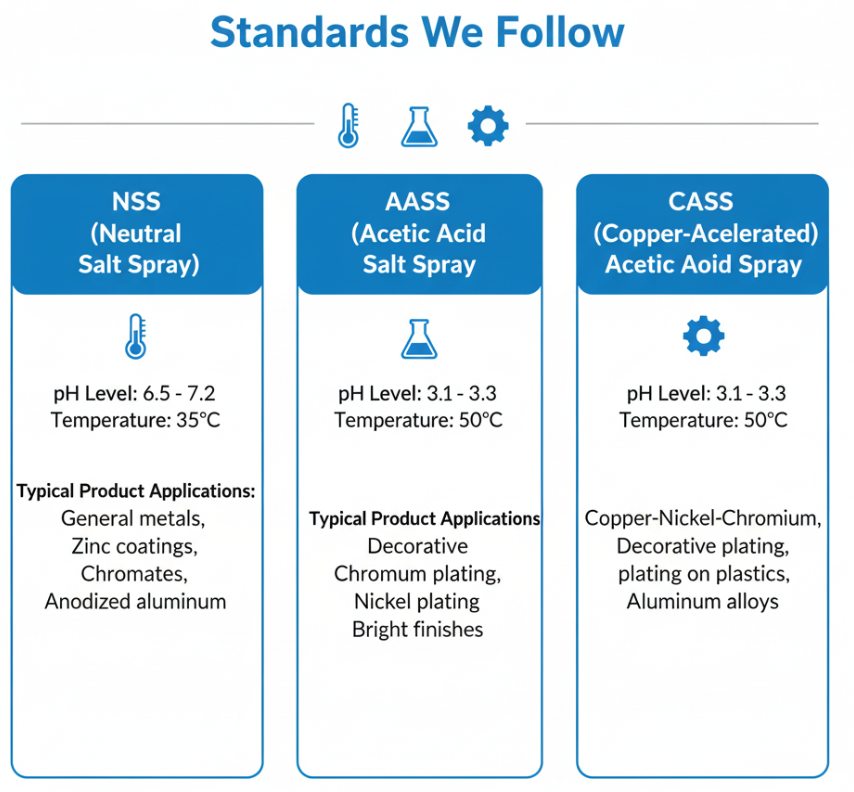

⭐ 3. Three Major Salt Spray Test Methods We Use

(1) Neutral Salt Spray (NSS)

pH: 6.5–7.2

Temperature: 35°C

Purpose: Standard corrosion test for coatings

(2) Acetic Acid Salt Spray (AASS)

pH: 3.1–3.3

Temperature: 35°C

Purpose: For nickel–chrome decorative coatings

(3) Copper-Accelerated Acetic Salt Spray (CASS)

pH: 3.1–3.3

Temperature: 50°C

Purpose: High-end finishes, PVD-coated parts

⭐ 4. How We Prepare & Test Each Sample

Based on your internal standard:

Samples must be clean, oil-free, damage-free

Placement angle: 15°–30°

Samples face upward to allow natural mist fall

Salt solution prepared to 50g/L NaCl concentration

Continuous testing with no interruption

Temperatures and pressures must remain within strict limits

⭐ 5. How Test Results Are Rated

We follow GB/T 6461 corrosion rating:

Rating Scale (RP):

RPResult Interpretation10Perfect – Pass7–9Acceptable5–6Engineer review required0–4Fail

Corrosion area (%) is calculated using the formula:

Rp = 3 (2 – Log A)

⭐ 6. Typical Testing Hours by Material

| Material | Surface Finish | Test Type | Required Hours |

|---|---|---|---|

| Brass | Chrome plating | AASS | 24h |

| Aluminum Alloy | Anodized | AASS | 24h |

| Stainless Steel | Polished | AASS | 24h |

| Stainless Steel Screws | Chrome | AASS | 24h |

This aligns with global industry expectations for bathroom hardware.

⭐ 7. Real-World Meaning for Buyers

Why does this matter to importers, brands, builders, and distributors?

Better warranty performance

Lower after-sales risk

Longer shelf-life for boxed products

Less risk of pitting, peeling, and discoloration

Consistency across batches

When we say “quality,” we show it through:

Testing photos

Corrosion ratings

Before-and-after comparisons

Continuous batch inspection records

⭐ 8. Why Wakebath’s Testing Exceeds Market Standards

EN 248 requires 24h NSS → We often test 200h NSS

High-end decorative parts pass 24h AASS

PVD-coated parts often pass CASS 48–72h

This allows our products to perform well in:

Coastal areas

High-humidity bathrooms

Hard-water environments

Commercial installations (hotels, gyms, apartments)

⭐ 9. Conclusion: Quality That’s Visible, Measurable, and Repeatable

Our salt spray testing is not a marketing story—it’s a daily operational routine.

Every test tells a story of commitment, engineering, and accountability.

📩 Want to see actual reports, photos, or test videos?

Visit www.wakebath.com or contact us for sample test data.

Disclaimer

The information is sourced from public channels and internal QC standards and is for reference only. If you have any objections, please contact us for deletion.

#SaltSprayTest

#CorrosionResistance

#EN248

#SurfaceFinishing

#BathroomHardware

#QualityControl

#ISO9227

#Wakebath

#NickelChrome

#MetalCoating

#PlatingQuality

#SurfaceTreatment

#AntiCorrosion

#MaterialEngineering

#BathroomHardware

#ShowerDoor

#ShowerEnclosure

#SanitaryWare

#BathFittings

#PlumbingProducts

#QualityControl

#QCInspection

#ProductTesting

#DurabilityMatters

#OEMManufacturer

#ChinaSupplier

#Wakebath

#MadeInChina

#ChinaManufacturer

#GuangdongFactory

#ExportQuality

#GlobalSourcing

#B2BSupplyChain

#TechnicalStandard

#ManufacturingProcess

#EngineeringTesting

#HowItsMade

#QualityStandards