Owning Aluminum Electroplating:

How Process Control Creates Long-Term Product Advantage

In today’s manufacturing environment, product differentiation no longer comes only from design or features.

Increasingly, it comes from process control — and from owning the critical steps behind product quality, consistency, and cost stability.

One of those critical steps is aluminum electroplating.

Why In-House Aluminum Electroplating Matters

Aluminum electroplating is not a simple finishing process.

It requires precise control over surface preparation, plating chemistry, process stability, and quality inspection. Small variations can lead to visible color shifts, uneven finishes, or long-term durability issues.

By operating our own aluminum electroplating facility, we maintain full control over every stage of the process — from raw aluminum components to final surface finish.

This allows us to deliver:

Stable and repeatable surface quality

High color consistency across production batches

Reliable durability for functional and decorative applications

For customers, this translates into predictable results — not just on one order, but across long-term production.

Mature Electroplating Capability Built Over Time

Electroplating aluminum at scale requires experience.

Over the years, we have continuously refined our processes, equipment, and inspection standards to ensure that aluminum components meet both aesthetic and performance expectations.

Our electroplated aluminum parts are designed to:

Maintain consistent appearance across different production runs

Resist wear and surface degradation in daily use

Meet the visual requirements of high-end architectural and bathroom hardware

This maturity is especially important in applications where surface finish is not optional, but integral to the product experience.

Applications: From Hardware Components to System-Level Consistency

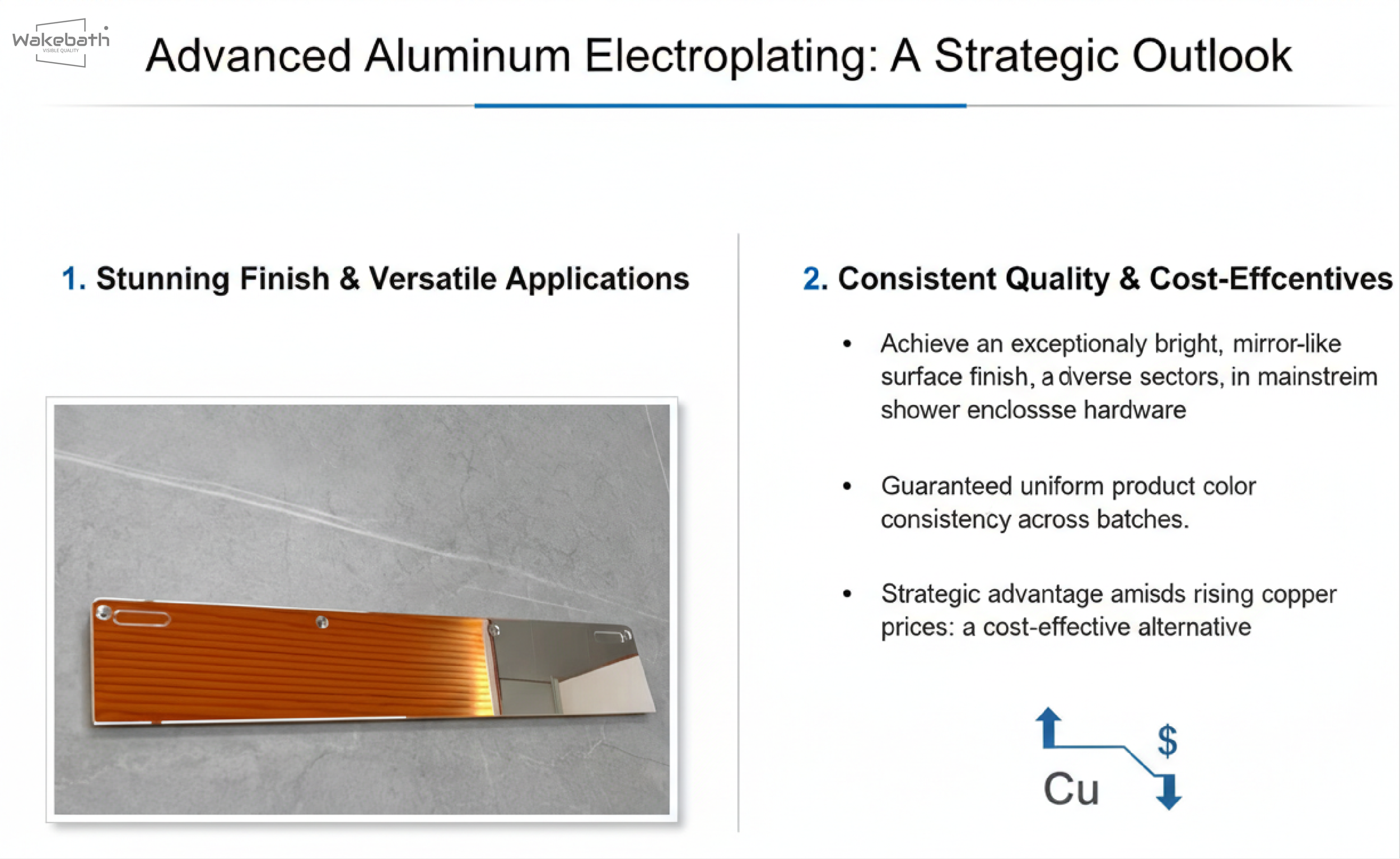

A well-executed aluminum electroplating finish is highly versatile.

Today, our electroplated aluminum components are widely used across multiple applications, including — but not limited to — shower enclosure hardware, where color uniformity, tactile quality, and long-term appearance are essential.

By controlling electroplating in-house, we are able to ensure:

Color consistency across handles, rollers, rails, and accessories

Visual alignment between different components within the same system

Stable appearance across multiple projects and delivery phases

For project-based customers, this level of consistency significantly reduces coordination risk and post-installation issues.

A Strategic Perspective: Aluminum in a Changing Cost Environment

Beyond quality, aluminum electroplating also plays an important role in long-term product and sourcing strategy.

With copper prices continuing to rise — and with no clear indication of a near-term reversal — many companies are reassessing material choices across their product lines.

High-quality electroplated aluminum components offer a viable alternative for a wide range of functional and decorative applications, supporting:

More predictable cost structures

Reduced exposure to volatile raw material pricing

Scalable production planning over longer product lifecycles

From a strategic standpoint, this is not a short-term substitution, but a forward-looking material approach.

Who This Capability Serves

Our in-house aluminum electroplating capability is designed to support decision-makers across different functions, including:

Product managers evaluating material and finish strategies

Cost-down and value engineering teams

Product development teams seeking stable, repeatable finishes

Procurement and buying teams focused on consistency and supply security

Strategic sourcing professionals planning long-term material roadmaps

In each case, the goal is the same: reduce uncertainty while maintaining product integrity.

Strength Comes from Owning the Process

True manufacturing strength is not always visible in the final product — but it is felt over time.

By owning aluminum electroplating as a core capability, we are able to offer more than components.

We offer control, consistency, and confidence — qualities that matter most when products are scaled, projects multiply, and markets become more volatile.

Sometimes, the strongest product advantage isn’t a new feature —

but a process that is fully understood, continuously refined, and firmly in-house.

If material strategy, surface consistency, and long-term cost stability matter to your products, this is a capability worth exploring.

#AluminumElectroplating

#ManufacturingCapability

#ProductStrategy

#CostEngineering

#StrategicSourcing

#ShowerHardware

#B2BManufacturing

Disclaimer

The information is sourced from public channels and internal QC standards and is for reference only. If you have any objections, please contact us for deletion.