💥 It’s Not the Glass That “Failed” — It’s Everything Around Your Shower Door

In many shower glass projects, when a panel suddenly explodes or shatters, the first reaction we hear is:

“Was the tempering done wrong?”

99% of the time — the glass itself meets all specs. The real issues are usually elsewhere — and you won’t spot them in a sample check.

Here’s what actually drives breakage (and validated by industry research):

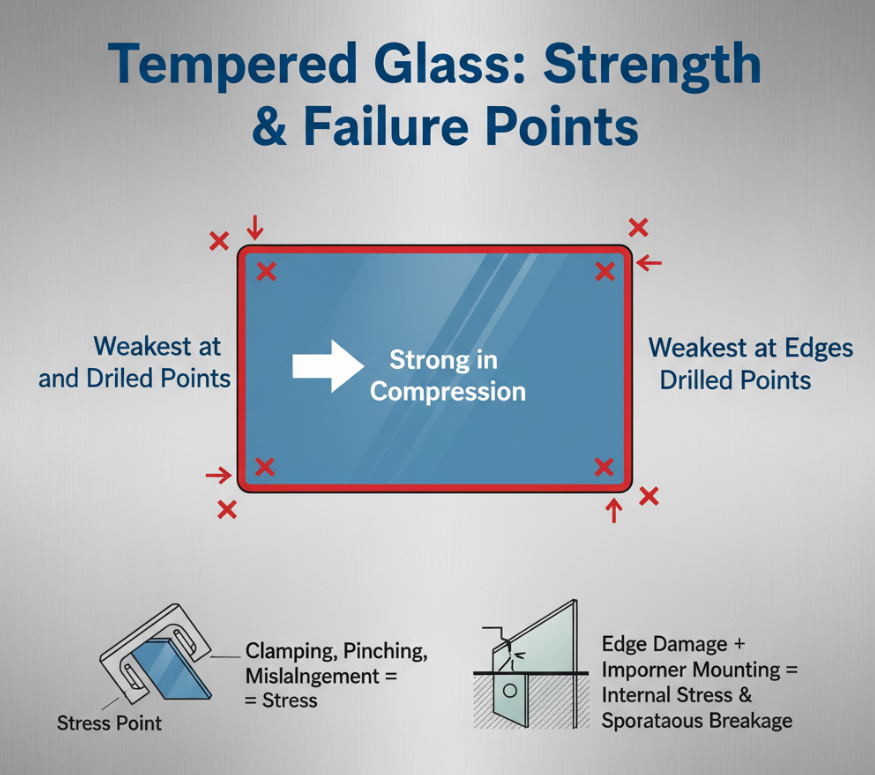

📌 1) Stress Concentration From Design & Hardware Tempered glass is strongest in compression, but weakest at edges and drilled points. Hardware that clamps, pinches or misaligns creates stress points that eventually fail. Industry analysis shows that edge damage and improper mounting lead to internal stress build-up and spontaneous breakage.

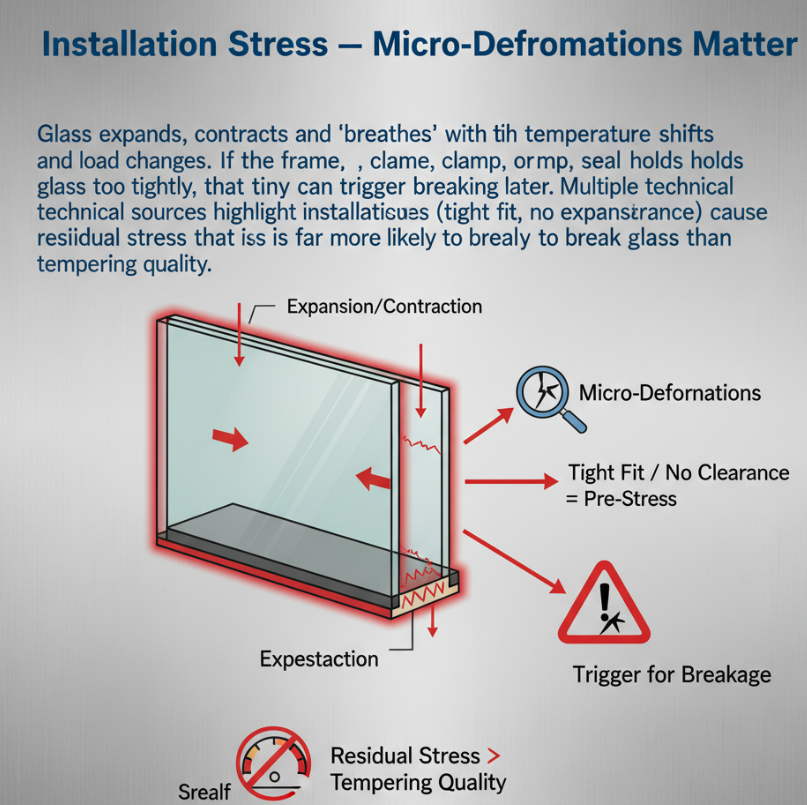

📌 2) Installation Stress — Micro-Deformations Matter Glass expands, contracts and “breathes” with temperature shifts and load changes. If the frame, clamp, or seal holds the glass too tightly, that tiny pre-stress can trigger breaking later. Multiple technical sources highlight that installation issues (tight fit, no expansion clearance) cause residual stress that is far more likely to break glass than tempering quality.

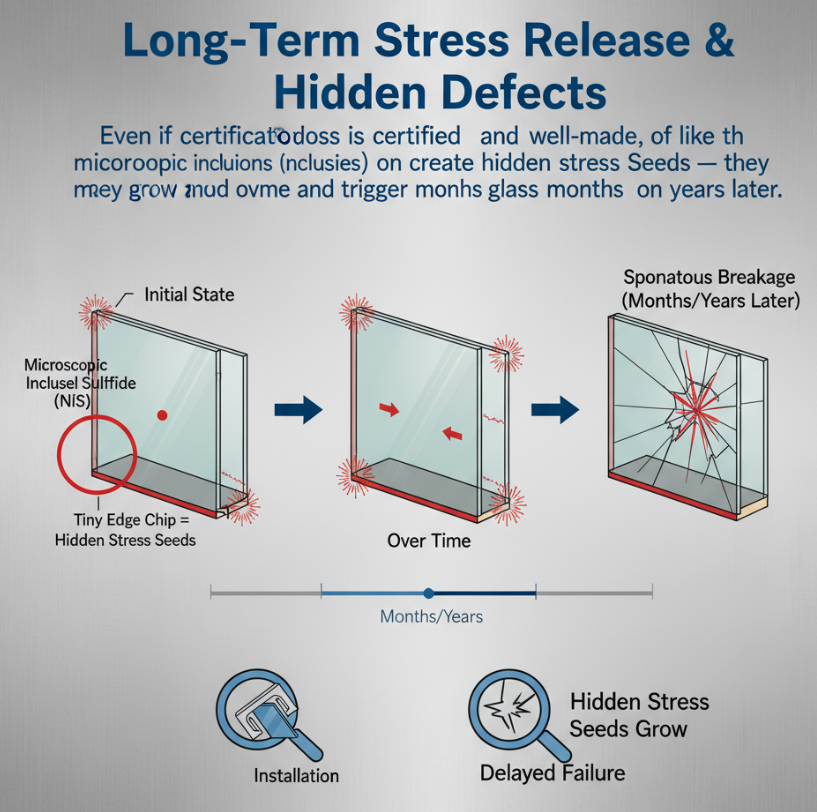

📌 3) Long-Term Stress Release & Hidden Defects Even if the glass is certified and well-made, microscopic inclusions (like nickel sulfide particles) or tiny edge chips can create hidden stress seeds — they may grow over time and trigger spontaneous breakage months or years later.

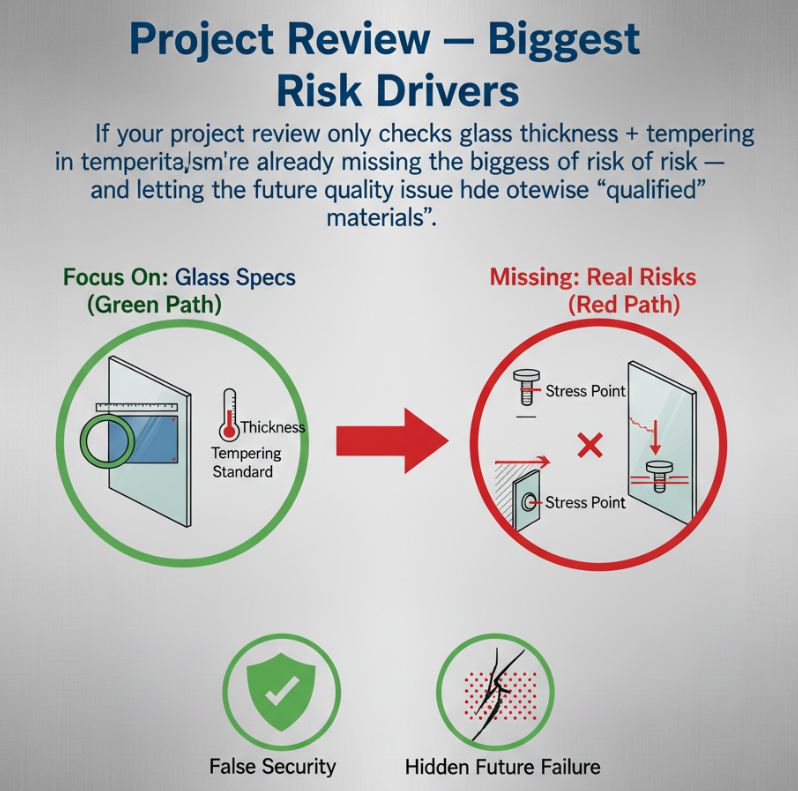

⚠️ Which means: If your project review only checks glass thickness + tempering standard, you’re already missing the biggest drivers of risk — and letting a future quality issue hide behind otherwise “qualified materials.”

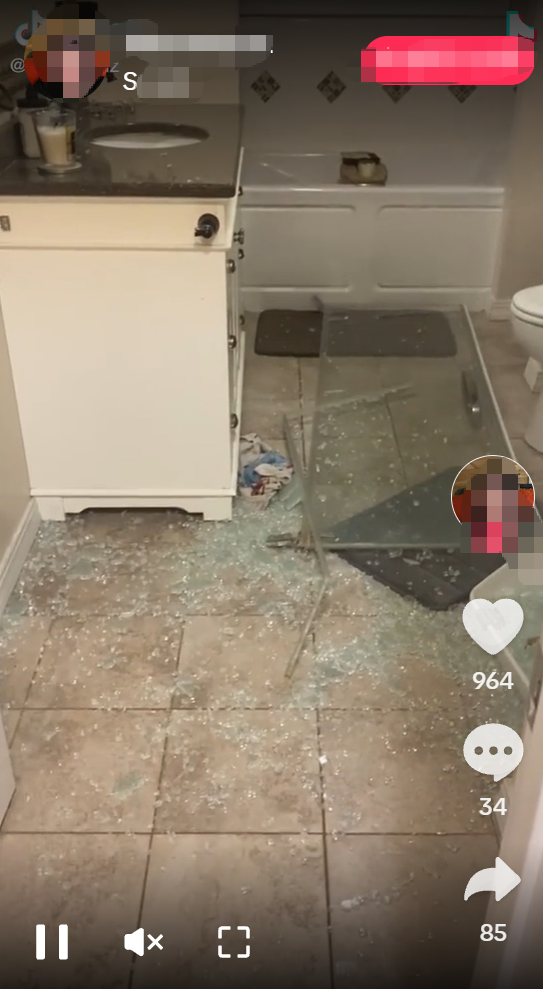

Case References (Real Incidents)

📍 In Virginia, a homeowner was injured when he bathroom shower glass exploded spontaneously, and the developer later acknowledged that tempered glass still carries breakage risk due to multiple internal/external factors over time.

📍 WASHINGTON (7News) — Some people say it sounded like an “explosion or gunfire."

That’s how two homeowners described the frightening moment when their glass shower door spontaneously exploded.

“Scared the crap out of me. What a mess, ” said Susan Fisher, of Michigan. Fisher said she heard a loud explosion at 3 a.m.

Takeaways for Project Teams

✔ Quality certification of glass alone is not enough.

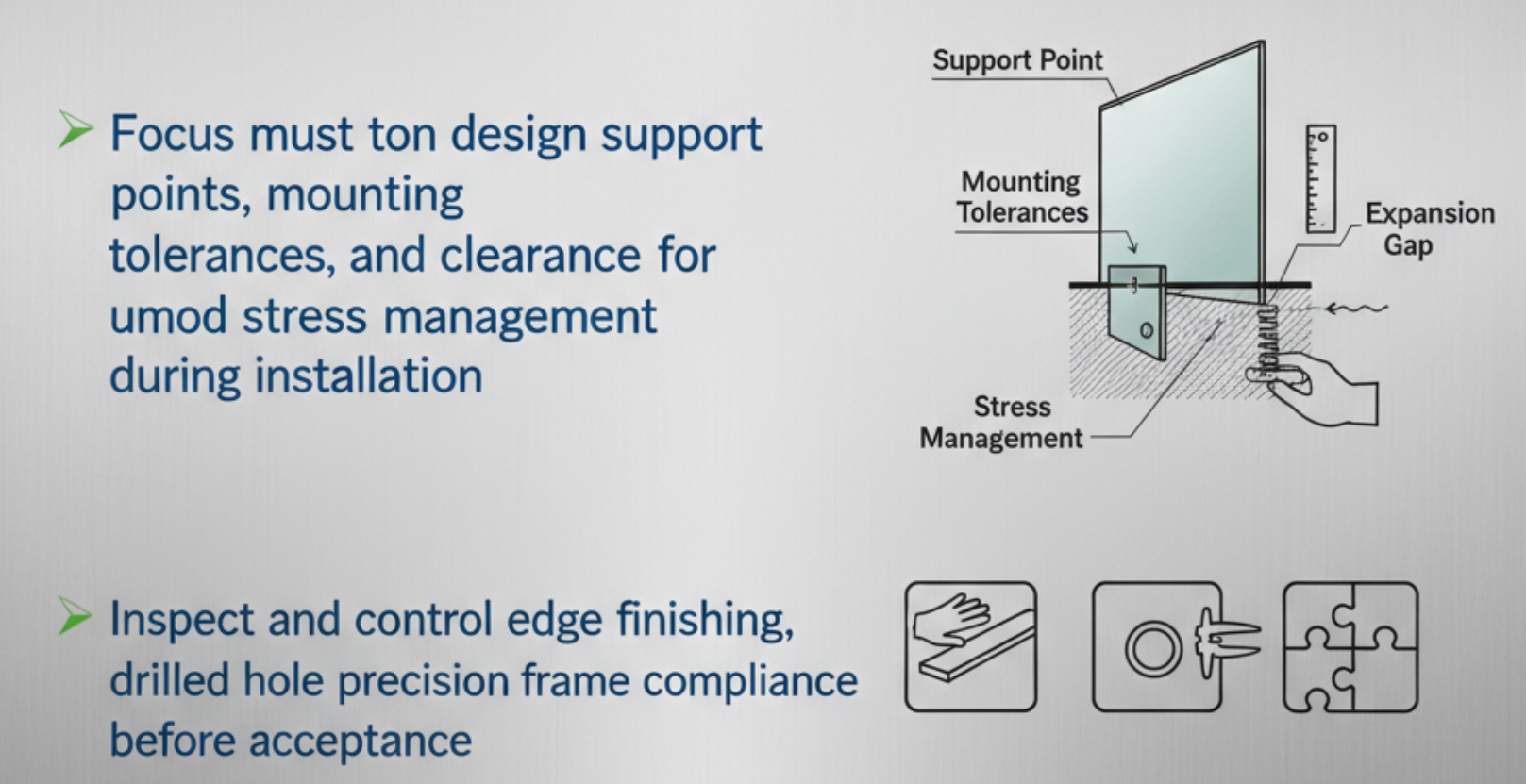

✔ Focus must be on design support points, mounting tolerances, clearance for expansion, and stress management during installation.

✔ Inspect and control edge finishing, drilled hole precision, and frame compliance before acceptance.

Because in the real world, the glass doesn’t “fail” — the forces do.

This is exactly why we now review stress points and installation tolerance as early as the design stage — not after breakage happens.

If you’ve seen similar issues on site, I'd be happy to exchange notes in a private conversation.

🌍www.wakebath.com

📧contact@wakebath.com

#ArchitecturalGlass #ShowerEnclosure #TemperedGlass

#GlassFailure #InstallationMatters

#HotelProjects #ProjectRisk

#ConstructionEngineering

Disclaimer

The information is sourced from public channels and internal QC standards and is for reference only. If you have any objections, please contact us for deletion.