8mm or 10mm? That question is already the wrong one.

This is something we get asked all the time:

“Do you recommend 8mm or 10mm glass?”

Honestly?

That question misses the real risk.

For shower enclosures, safety is never decided by thickness alone.

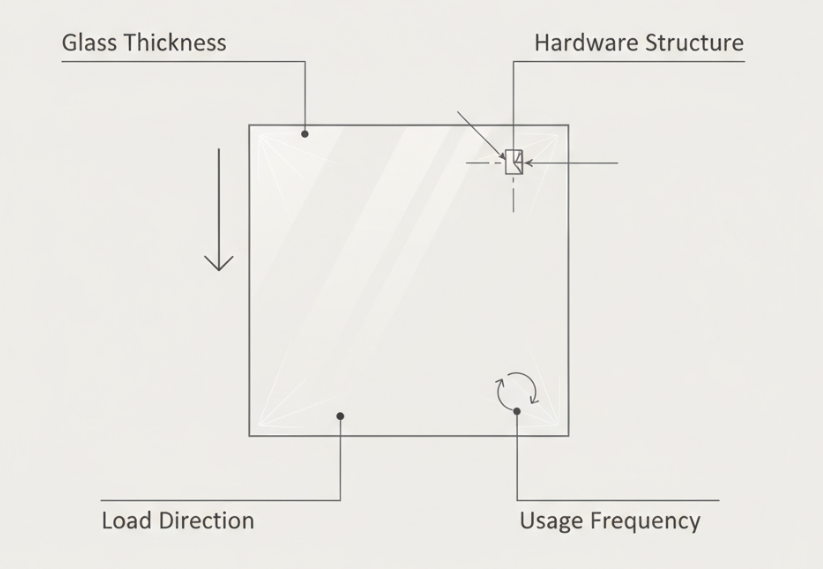

What really matters is the system, not a single number:

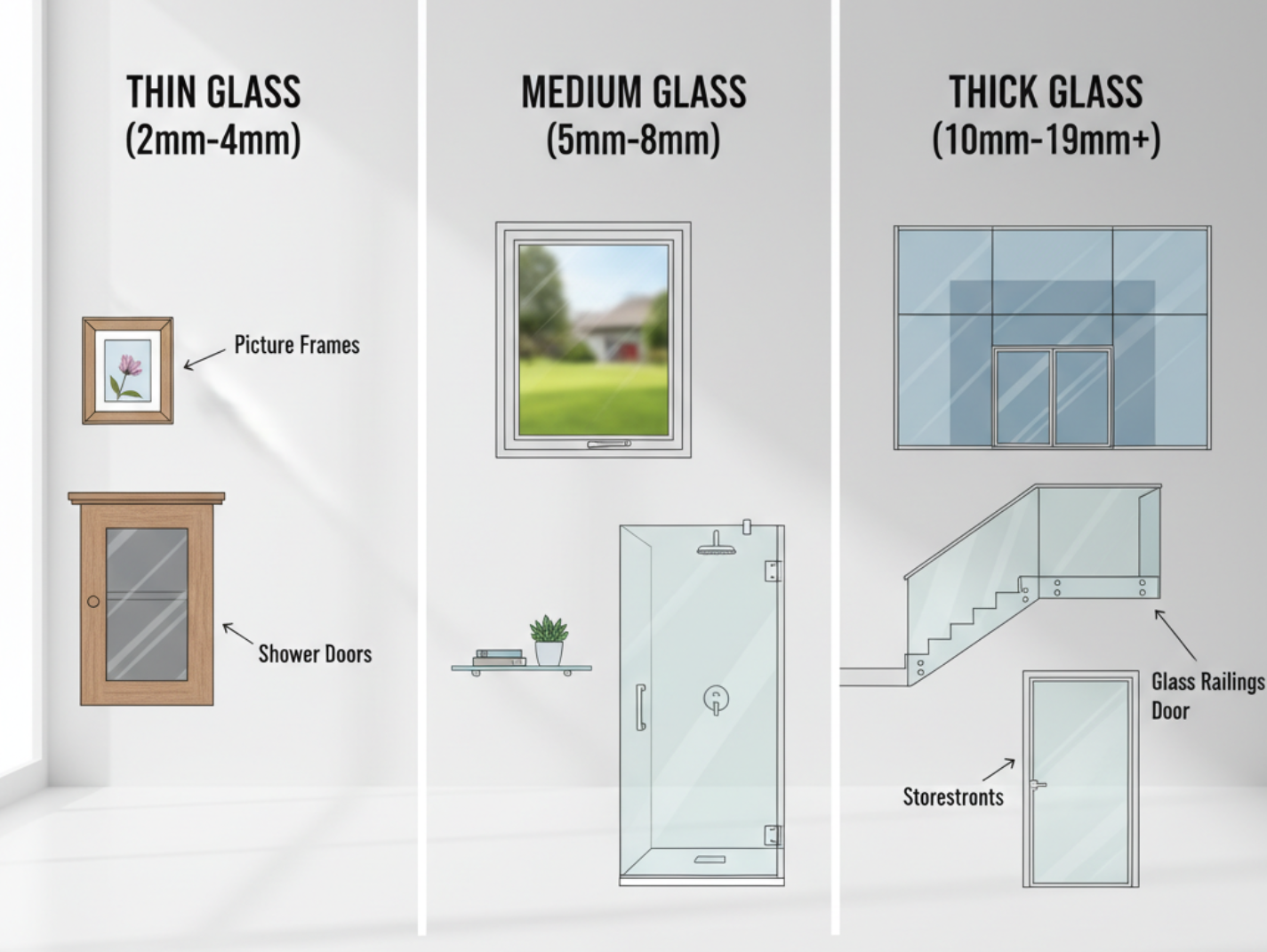

Glass Thickness:

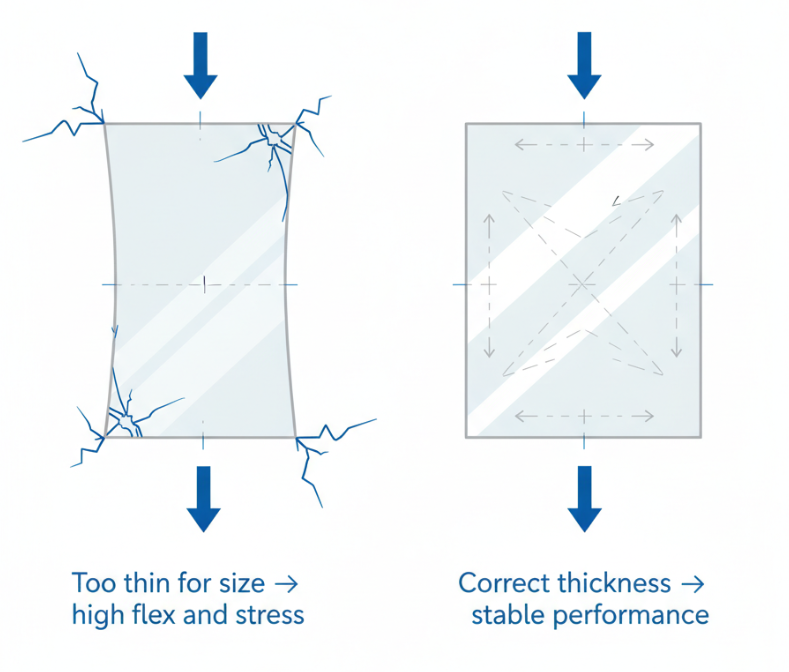

Real Risk: If the glass is too thin for its size or intended load, it's highly susceptible to breaking from impact, pressure (like wind load on a large window), or even its own weight if unsupported. Thin glass also flexes more, which can lead to stress cracks over time, especially around fixings.

Mitigation: Choose a thickness appropriate for the pane's dimensions, the type of glass (annealed, tempered, laminated), and the expected loads. Building codes often provide minimum thickness requirements for safety-critical applications.

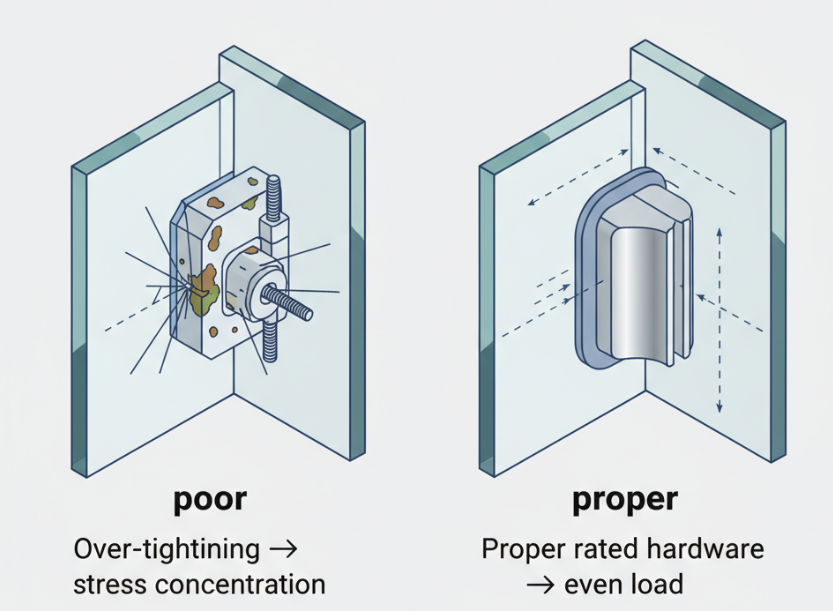

Hardware Structure (Fixings and Support System):

Real Risk: The strongest glass is only as good as what holds it.

Weak/Incompatible Hardware: Using hardware that isn't rated for the glass's weight or the expected forces can lead to the glass falling out, sagging, or breaking at the connection points.

Improper Installation of Hardware: Over-tightening fixings can create stress points in the glass, leading to cracks or spontaneous breakage. Under-tightening can cause the glass to become loose and wobble, creating pinch points or allowing it to fall.

Corrosion/Degradation: If hardware corrodes or degrades over time, its structural integrity is compromised, leading to potential failure.

Mitigation: Use high-quality, corrosion-resistant hardware specifically designed for glass (e.g., stainless steel clamps, standoffs, channels). Ensure hardware is properly rated for the glass's weight and the application. Follow manufacturer's installation guidelines meticulously, ensuring even pressure and using gaskets or buffers where glass meets metal. Regular inspection for wear and tear is also important.

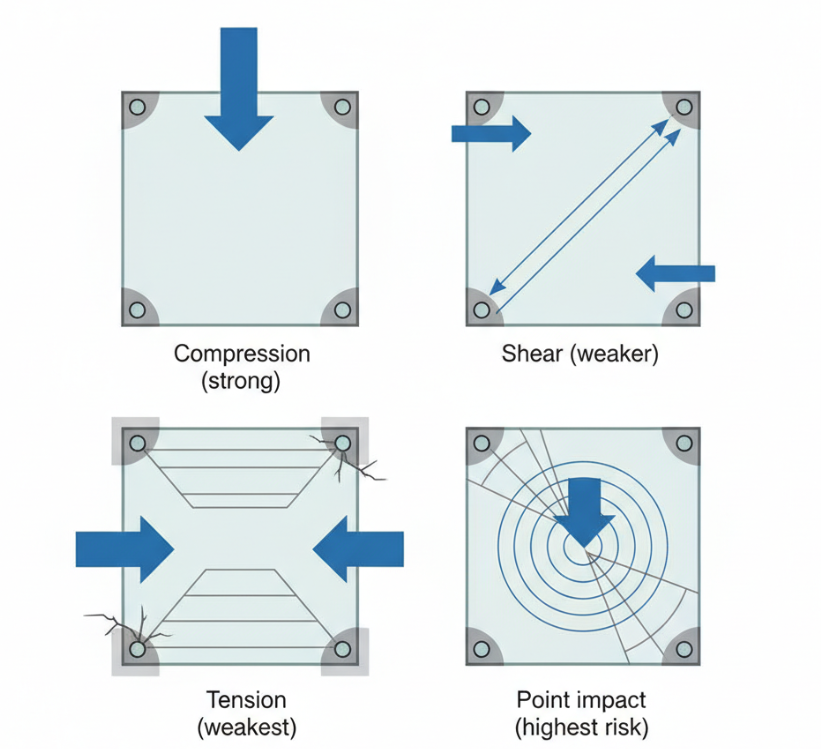

Load Direction:

Real Risk: Glass has different strengths depending on how the load is applied.

Direct Impact: A sharp, concentrated force (e.g., a hammer blow) is far more likely to break glass than a diffused force.

Shear vs. Compression: Glass is very strong in compression (squeezing) but weaker in shear (forces pushing parallel to the surface) and tension (pulling apart).

Uneven Loading: If a load is applied unevenly, it can create localized stress points that exceed the glass's capacity, even if the overall load is within limits. For example, leaning heavily on one corner of a glass table.

Mitigation: Design glass elements to distribute loads evenly. For railings and barriers, consider the direction of potential human impact. For shelves, ensure items are placed centrally and the load is spread out. For glass floors, design for vertical dead and live loads, and also for potential point impacts. Specify the correct glass type (tempered for impact resistance, laminated for post-breakage integrity) based on likely load directions.

Usage Frequency:

Real Risk: High-traffic areas or frequently used glass elements experience more wear and tear, increasing the risk of:

Accumulated Damage: More opportunities for minor impacts, scratches, or chips that weaken the glass over time.

Hardware Fatigue: Fixings, hinges, and sliding mechanisms on glass doors or partitions will wear out faster, potentially leading to misalignment, sagging, or failure.

Increased Exposure to Stress: Glass in doors that swing frequently or partitions that slide often will undergo repetitive stress.

Mitigation: For high-frequency usage, always specify robust, high-quality, thicker tempered or laminated glass. Use heavy-duty, commercial-grade hardware that can withstand repeated cycles. Implement a regular maintenance schedule to inspect for wear, tighten loose fixings, and address any minor damage before it becomes critical.

Here’s the part many people don’t expect:

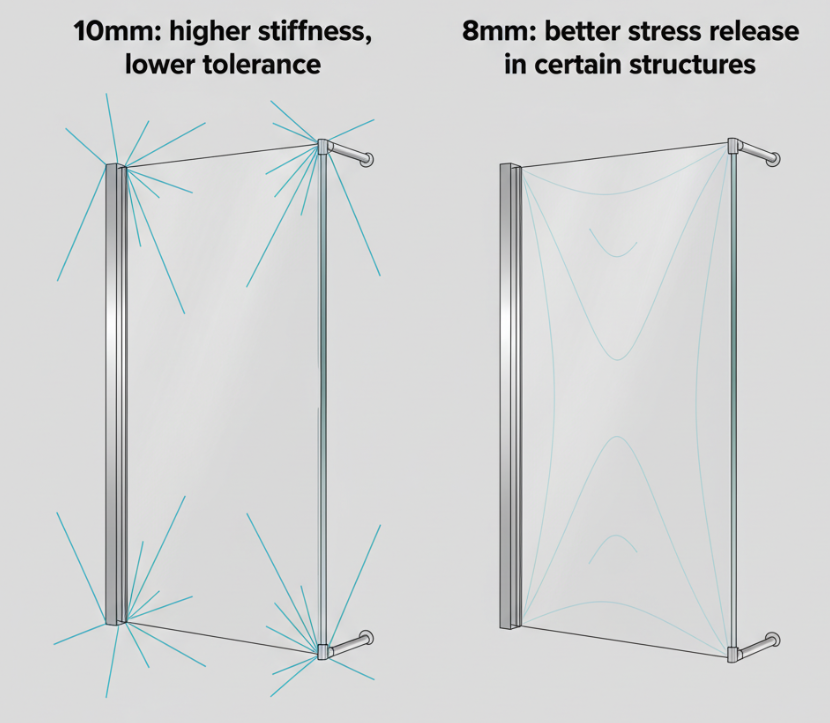

In certain structures, 10mm glass can actually accumulate stress more easily than 8mm.

Thicker glass is stiffer.

Stiffer glass means less tolerance for installation deviation, frame movement, and long-term stress release.

So when failures happen,

it’s rarely because the glass was wrong.

It’s because the decision logic was wrong.

Choosing glass by thickness alone feels “safe”, but in real projects, it’s often the opposite.

Key takeaways for project teams:

• Glass safety is a system decision, not a thickness decision

• Thicker glass increases stiffness, but reduces tolerance

• Hardware, load direction, and usage frequency often matter more than numbers

• Many failures are predictable — if the right questions are asked early

If you’re specifying shower glass for a real project, it may be worth revisiting the question — before locking the thickness.

Welcome to leave your comment.

#ArchitecturalGlass

#ShowerEnclosure

#GlassEngineering

#InstallationMatters

#ProjectRisk

#BuildingMaterials

#HotelProjects

#ConstructionEngineering